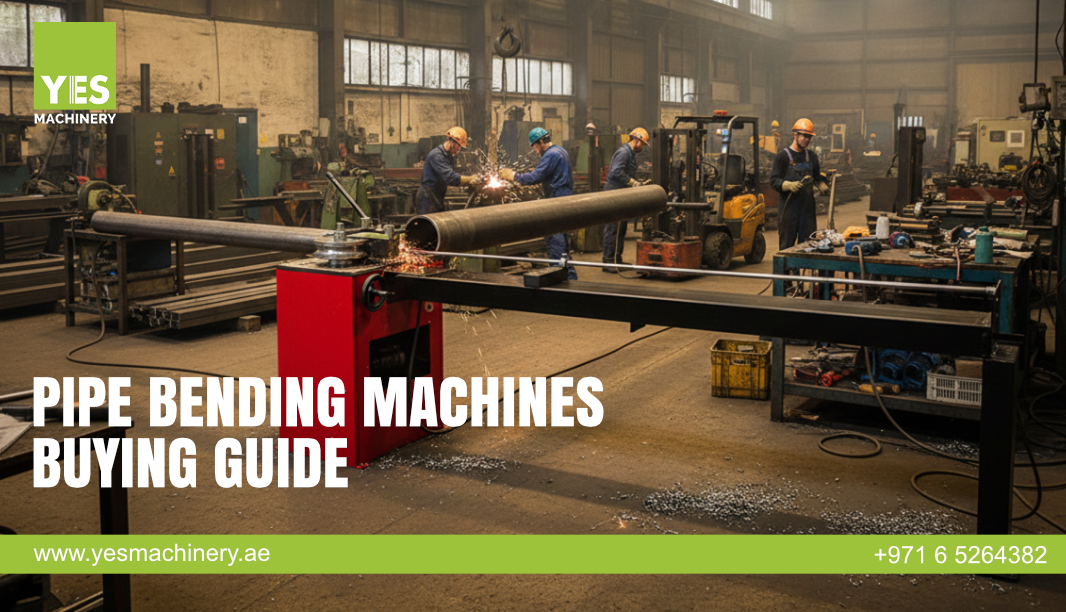

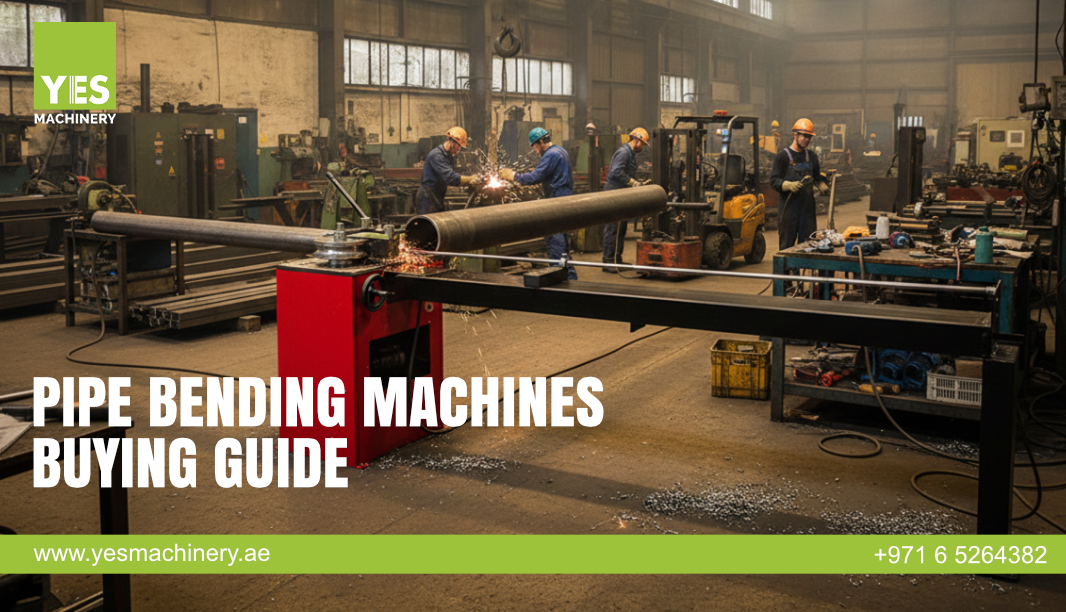

Pipe Bending Machines Buying Guide

- Category Machines

Imagine a situation where you are installing a piping system using straight pipes? For every change in direction you would need to cut, fit, weld and seal, which can cause a lot of issues, as every elbow or welded joint can become a potential weak spot. This can create heat-affected zones, fatigue cracking and many other issues.

Pipe bending machines solve this issue by shaping straight pipes into precise angles and curves without needing to cut or weld. This blog will help you in buying the right pipe bending machine.

What are pipe bending machines?

Pipe benders are crucial machines that help to bend pipes of different thickness and diameter by applying bending torques shaping them along the required angle and radius. This ensures that the pipes are bent without forming any cracks or wrinkles.

The bending process involves securing the pipe, using dies to prevent the pipes from collapsing and then applying the pressure to create specific bend.

There are different types of bending machines such as:

- Manual Pipe Bending Machines:

These pipe benders are operated manually and are suitable to create basic bends required for small scale projects. It typically consists of a lever, a die and clamps that are activated when the lever is pulled.

- Hydraulic Tube Bending Machines:

Here the hydraulic pressure bends the pipe along the desired angle. These machines are well suited to larger and thicker pipes.

-CNC Pipe Bending Machines:

In a CNC bending machine the servo motor is used for the precise control of bending angle, radius and tube feeding ensuring consistent and accurate operation. The other processes such as core feeding, annealing, clamping and pushing are done by the hydraulic drive. CNC pipe benders find their application in demanding sectors such as automotive manufacturing, industrial automation and other large scale industrial projects.

How To Choose The Right Pipe Bending Machine

- Select the right type of bending machine

Understand the different types of CNC bend machines such as manual, CNC, hydraulic pipe benders and the like as mentioned above. So choose the machine that matches the production goals.

- Consider the pipe material and specifications

Different pipe materials and sizes may need different bending requirements. Ensure that the material is compatible, because certain metals such as carbon steel, aluminum or copper react differently to bending processes. Thickness is also another factor- thicker the pipe is, the more powerful the clamping force should be. Therefore make sure to choose a machine that can handle

- Define the bend requirements

Consider the bend requirements of the bending project. Certain projects may require complex angles, curves and a specific radius. In such situations opting for CNC and similar advanced benders will be a good choice. In short, if the project requires consistent and flawless operation, consider using more frontline benders.

- Portability of the bender

If the project requires the machines to be moved along multiple locations within the workspace, then consider investing in compact and mobile models. Also consider the proximity of the workspace and select a machine that fits the environment.

- Check for the safety features

Safety is a non-negotiable factor. Therefore ensure that the machine is equipped with all the necessary safety features such as emergency stops, safety shields, alarm systems and auto shut-off mechanisms.

- Budget Considerations

Considering the budget limit is important. For low volume and small scale projects manual or hydraulic pipe benders will be an apt choice and are budget friendly considering the low upfront cost.

For large scale industrial projects CNC machines will be required which have a high upfront cost. But CNC machines tend to be more cost effective over time owing to their efficiency, reduced labour cost and reduced material wastage.

So consider the project volume, energy consumption, maintenance cost and several other factors before final purcahse.

- Ensure Proper Service and Aftersales Support

Partner with a reliable supplier or manufacturer. Check thier expertise and experience in the respective field. Make sure that they provide proper customer service, spare parts and aftersales support.

Conclusion

Pipe bending machines are integral to the manufacturing sector. You shouldn’t go with just any pipe bender- choose the most durable, reliable and advanced machines that deliver accurate results, minimize downtime and ensure optimal productivity.

At YES Machinery we supply top-tier pipe bending machines suited for versatile applications. We ensure that our pipe bending machines offer precise and efficient solutions that you can rely on.

Related Blogs

Search

Latest Blog

Pipe Bending Machines Buying Guide

How Important Are Deburring Machines in Metal Finishing?

Role of Electric Screwdrivers in Industrial Operations

Categories

- Assembly and Lean

- Cleaning Machines

- Cleaning Robots

- Cutting, Notching, Punching

- Edge Preperation

- Grinding Machines

- Industrial Vacuum Cleaners

- Lifting

- Lifting and Manipulation

- Machines

- Marking Solutions

- Metal Forming

- Metal Joining and Fastening

- Packing

- Pipe Handling

- Storage Solutions

- Sweeper Tool Carrier

- Vacuum lifting machine

- Warehousing and Storage

- Welding